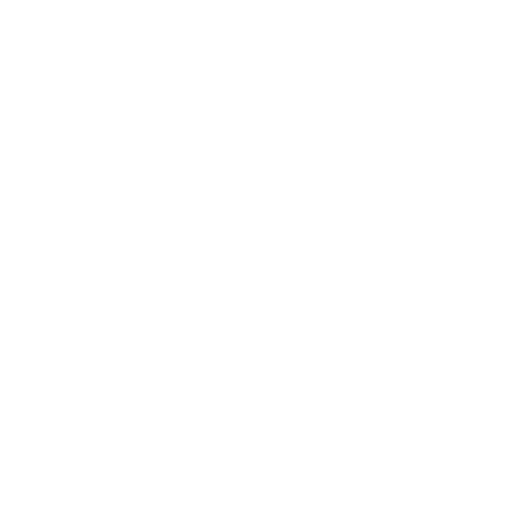

3D Laser Scanning for Ballast Water Treatment Systems

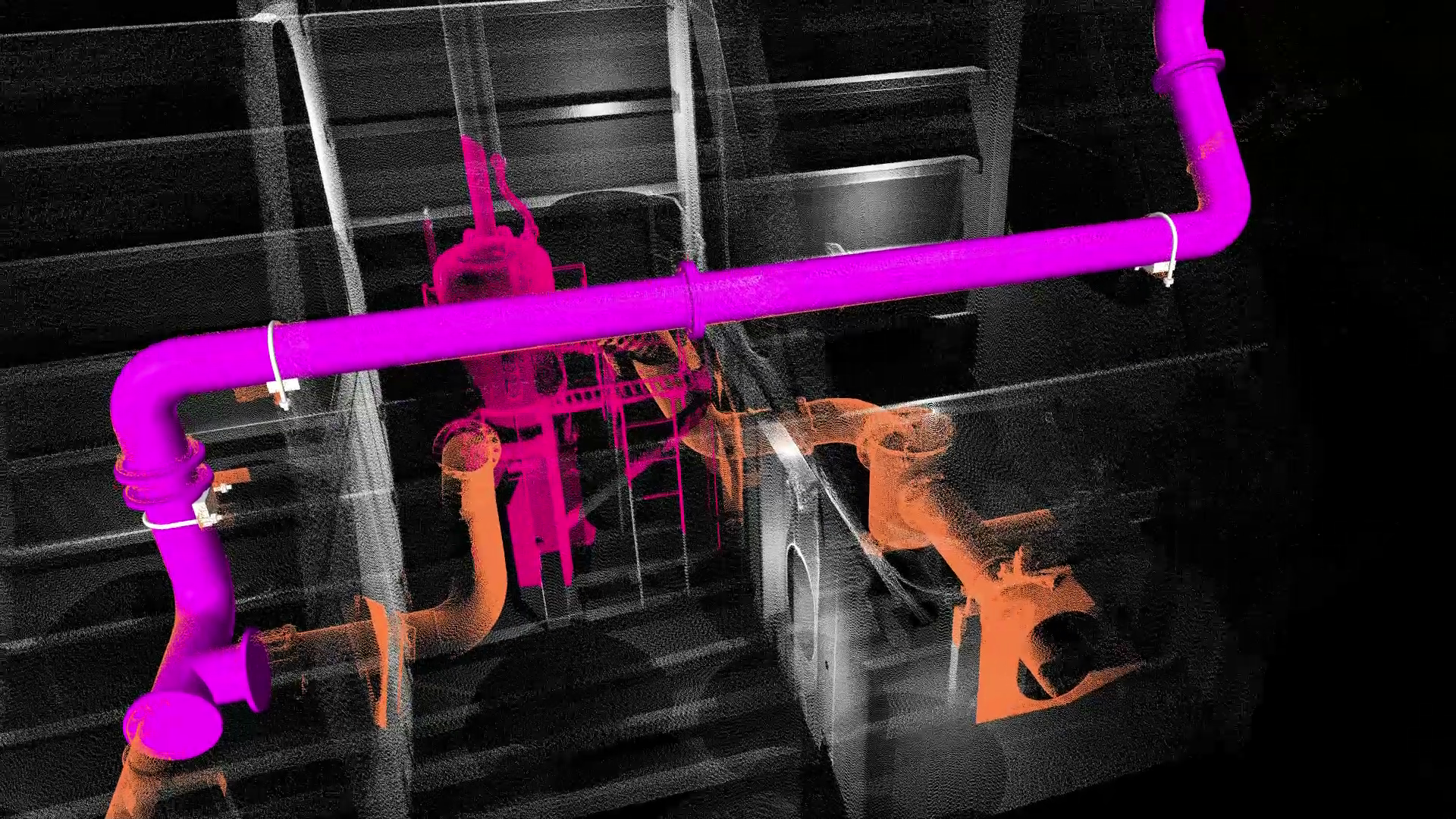

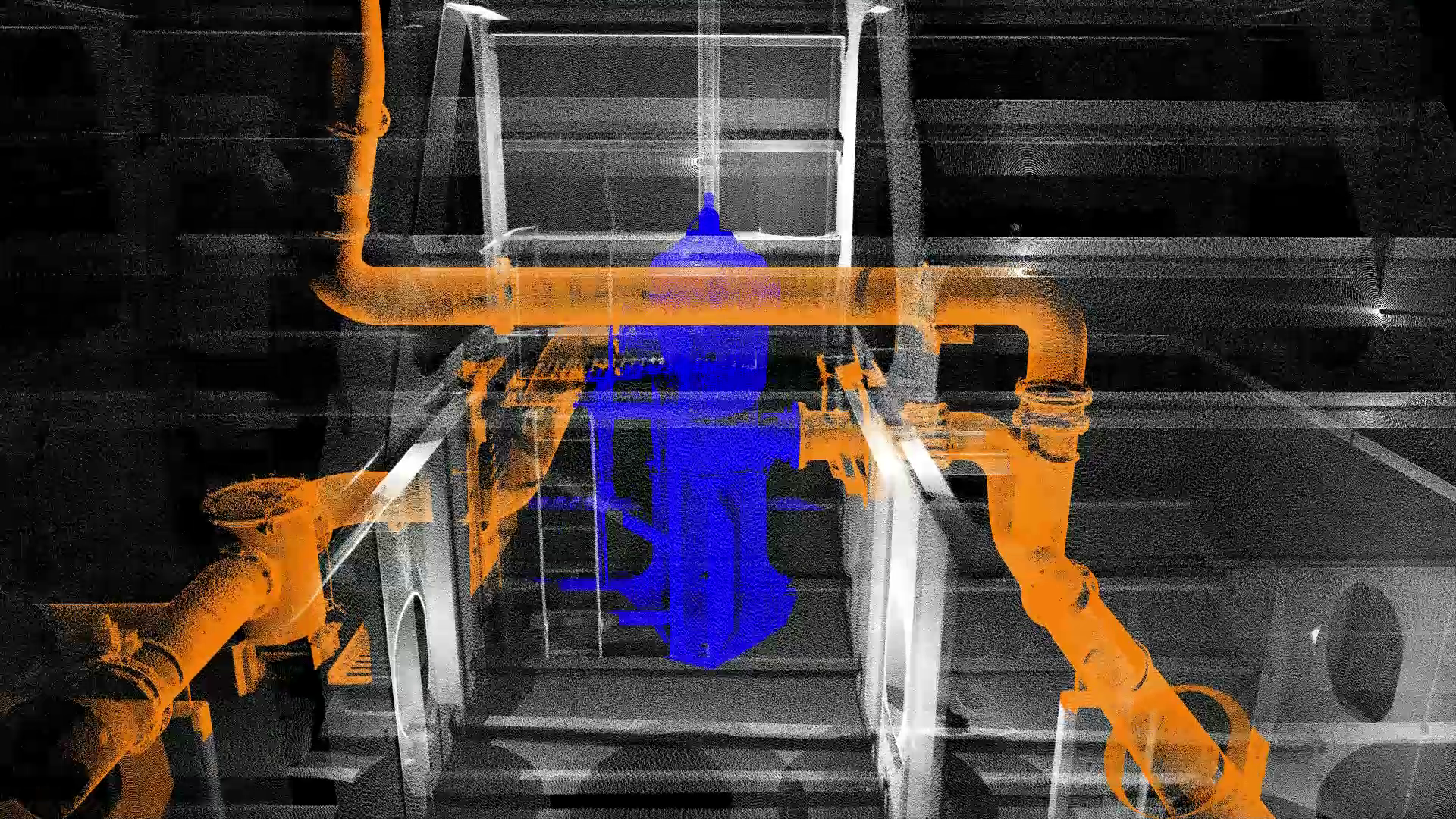

3D laser scan to capture the “as-built” conditions of your ship or vessel before installing a ballast water treatment system or bwts. Scanning provides accurate measurements and high detail of existing pipe and structure.

Benefits of 3D laser scanning include:

- Measurements can be taken from a laptop or office computer eliminating multiple hand measurements in the field.

- Reduce clashes in your design work. Laser scanning provides a 3D environment where proper placement, available space, and pipe routing can be easily verified.

- Vessels do not necessarily need to be dry docked. Scanning can often be performed without disrupting normal operations.

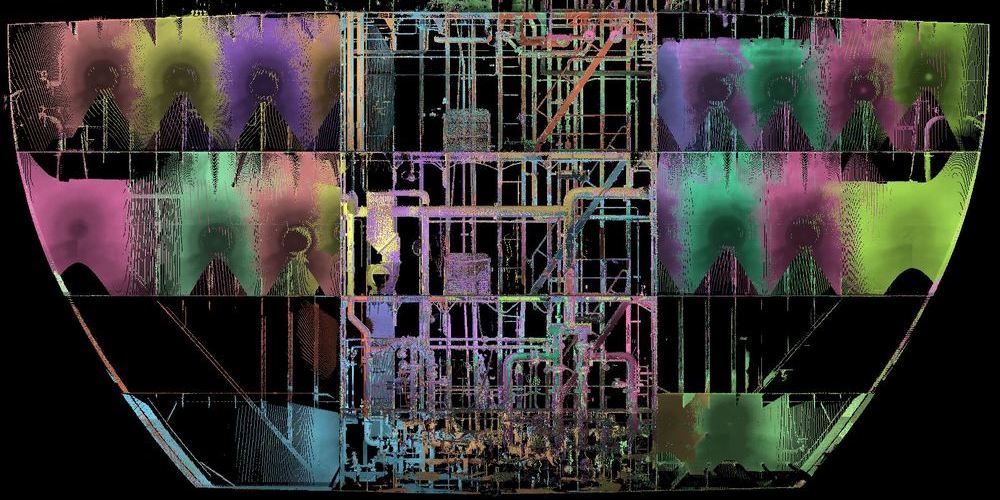

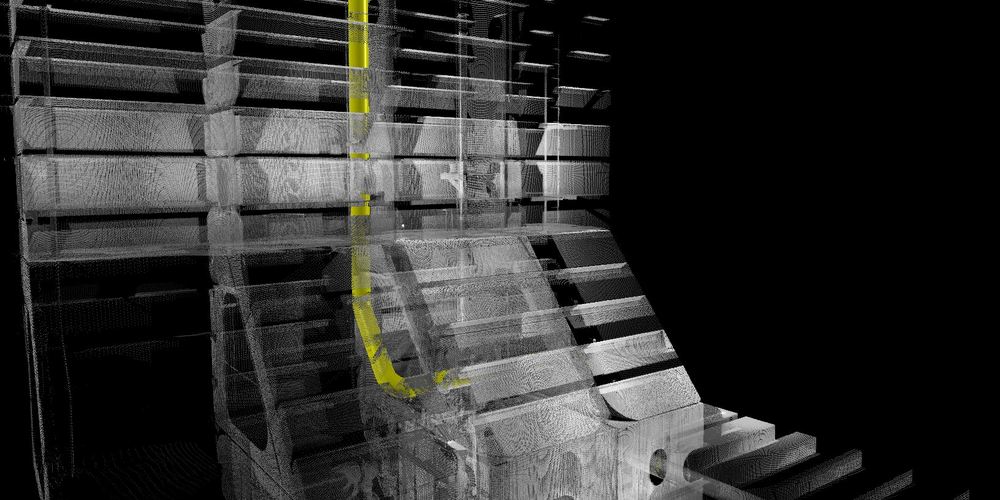

- We also offer surface fitting of hulls, modeling of bulkheads or structure, and center line extraction of existing pipe. Our pipe center lines can be given to your pipe designer where they can trace over the lines or snap-to them for accurate routing of existing pipe systems.

We can provide the following deliverables in your choice of grayscale or colorized:

- Registered fls files.

- Registered ReCap project.

- Registered E57 files.

- CAD models of piping systems, tie-ins, bulkheads, and structure.

Registered scans and scan projects can be set to the coordinates of your choice. To align to ship coordinates, please provide a General Arrangement drawing if available.

BWTS – Fitting As-Built Piping to 3D Laser Scans

3D Scanning Submersible Pumps for Ballast Water Treatment System

See Also As-Built Piping with 3D Laser Scanning